KEY POINTS

-

3D concrete printing (3DCP) is transitioning from pilot projects to full-scale commercialization, with large-scale deployments, such as Walmart buildings and other commercial retail projects.

-

3DCP technology offers faster, cleaner, and more consistent construction, reducing costs by 15% and waste by 55% compared to traditional methods.

-

Around the world, 3DCP is gaining traction, with projects like a train station in Japan built in six hours and a two-story house in Australia completed in 10.5 hours.

3D concrete printing is being touted as the wave of the future for commercial building developments as the process moves beyond one-off pilots into full-scale commercialization for retail giants.

Alquist, a pioneer in 3D construction printing based in Colorado, is partnering with Hugg & Hall, a construction and equipment rental dealer, and general contractor FMGI, to print more than a dozen new large-scale Walmart buildings, along with buildings for other commercial retailers.

The deal marks the largest-scale commercial real estate deployment of the 3D concrete printing technology in U.S. history.

3D Concrete Printing Moves from Pilots to Full-Scale Commercialization

Although adoption of the new technology is on the rise in the homebuilding segment of construction, uptake for commercial construction has been slower as larger printers are needed.

Alquist is hoping to change that by scaling the technology nationwide for commercial buildings. The company designs and builds large-scale printers and develops the code and software to operate them.

Alquist launched a partnership model with Hugg & Hall and FMGI. Under the deal, FMGI will lease Alquist printers that are financed and serviced by Hugg & Hall.

The deal enables Alquist to sell, lease, and rent its proprietary equipment and training methods to the broader construction industry, expanding access to commercial 3D construction printing (3DCP) at scale.

The first project under the new deal is a Walmart store in Lamar, Missouri. It is Alquist’s third Walmart project. Going forward, Alquist will collaborate with Walmart and other national retailers while exploring additional strategic partnerships to expand its model across the country.

“For the first time ever in our industry, we have the right partners in place to scale 3DCP at a massive level,” says Patrick Callahan, CEO of Alquist. “For years, 3DCP has been an emerging idea. Now, it’s a proven solution being deployed by some of the nation’s largest companies.

“This partnership shows what’s possible when innovation and collaboration align, and it’s only the beginning of what 3D printing will do for commercial construction.”

Darin Ross, president and CEO of FMGI, says the company was drawn to Alquist because the technology is so practical.

“It’s faster to mobilize, cleaner onsite, and delivers consistent quality in every print,” he says. “For us, this partnership is about transforming how large-scale projects actually get done.”

John Hugg, president of Hugg & Hall, says the company is excited to partner with Alquist and FMGI to bring a new generation of construction equipment to market.

The projects for Walmart and the others vary in size, scope, and regional application.

Efficiency and Sustainability “Redefine” Commercial Construction

Alquist states its robotic 3D printing systems will deliver structural walls and infrastructure elements more efficiently and sustainably than traditional construction methods.

“This is the moment 3DCP becomes commercialized at scale,” said company founder Zachary Mannheimer. “We’ve spent years proving that this technology works; now we’re putting it to work.

“Through this partnership, Alquist is helping redefine how America builds. Together, we’re accelerating construction, cutting waste, and building a stronger, more sustainable foundation for the future.”

In preparation for a busy year, Alquist has expanded its network with education and industry partnerships. The company continues to work with Aims Community College in northern Colorado and other residential builders to train the workforce of the future and advance sustainable building solutions, with additional education partnerships to be announced soon.

In May, Alquist successfully showcased its technology by wrapping up a new, 5,000-square-foot Walmart expansion project at the Owens Cross Roads Supercenter in Alabama in 75 hours.

A five-person team from Alquist used two printers to construct 26-foot-high concrete walls over the course of seven working days. For the company, it was the fastest timeline for a project of such scale.

Sika USA provided the concrete mix for the project, and FMGI managed site coordination to ensure there was smooth integration between printed elements and other construction tasks.

The build cost 15 percent less and produced 55 percent less waste than the first 3DCP building, an 8,000 Walmart Supercenter expansion in Athens, Tenn. The crew had budgeted for 130 bags of mix, but only 94 were actually needed – a 28 percent drop.

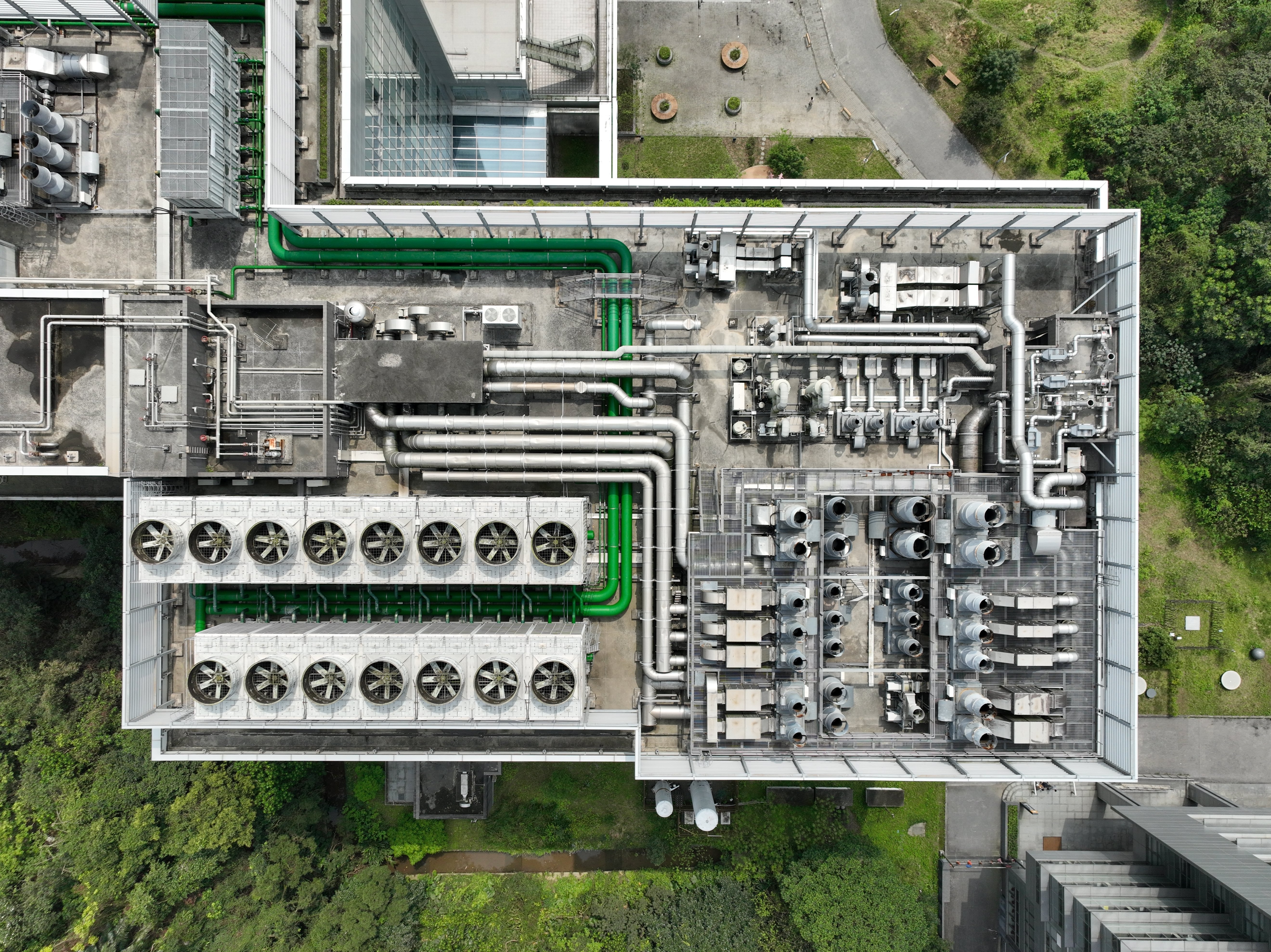

Robots and 3D concrete printing by Alquist 3D constructed the walls of this 5,000-square-foot Walmart expansion. Image: Alquist3d.com

Global Momentum Highlights the Future of 3DCP

Around the world, 3D-printed concrete is making a splash. In Japan, for example, the West Japan Railway Company partnered with JR West Innovations Co. and Serendix Inc. to build a single-story train station building in six hours. In Australia, Contec Australia used 3D concrete printing to build a two-story, 155-square-metre house in Perth’s northern suburbs in 10.5 hours.

Alquist isn’t the only company looking at 3D concrete printing for commercial construction.

Earlier this year, Icon Build, a 3D technology company, partnered with Lenmar to build 100 homes in Georgetown, Texas, just outside Austin.

Stay Connected

Stay connected with ConstructConnect News, your source for construction economy insights, market trends, and project news.

About ConstructConnect

At ConstructConnect, our software solutions provide the information that construction professionals need to start every project on a solid foundation. For more than 100 years, our keen insights and market intelligence have empowered commercial firms, building product manufacturers, trade contractors, and architects to make data-driven decisions, streamline preconstruction workflows, and maximize their productivity. Our newest offerings—including our comprehensive, AI-assisted software—help our clients find, bid on, and win more projects.

ConstructConnect operates as a business unit of Roper Technologies (Nasdaq: ROP), a constituent of the Nasdaq 100, S&P 500, and Fortune 1000.

For more information, visit constructconnect.com